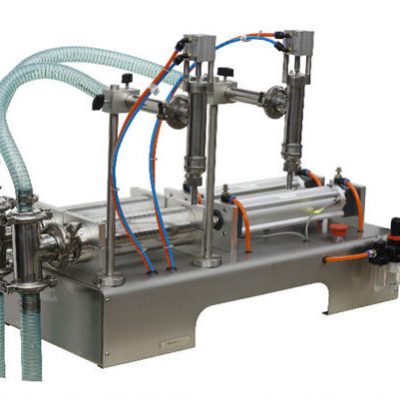

2合1自动瓶装和液体封盖机

1. The material which contact directly with the oil is the SUS304 (GMP), made in China.

2. The 3-in-1 is mainly used to food, daily,cosmetic Paste filling and capping.

3,灌装机采用世界知名品牌电气元件,故障率低,性能可靠,使用寿命长。

4.触摸屏显示简单的灌装量和灌装速度调节,外形美观。

5.具有无瓶无灌装,液位自动控制充电功能。不需要更换零件,各种规格的瓶子形状可以非常快速地更换,无需更换零件。

6.灌装头配有专用防喷器,灌装无拉丝,滴水现象。

工作流程:

自动灌装线有伺服系统。人工将空瓶放入输送带,由PLC控制系统按顺序自动进入灌装线,完成物料灌装。

组态:

1.机器材质:SUS304

2.接触材料:SUS316

3.休息部件材料:刚性氧化铝

4.灌装伺服电机:台湾东元

5. PLC控制系统:西门子

6.触摸屏:西门子

7.光电传感器组件:韩国AUTONICS

8.低压电器:施耐德

技术参数

| 填充量 | 100-200ml (可根据您的尺寸定制) | 机器功率 | 1.5KW |

| 填充速度 | 40-60B / M | 电源电压 | AC 220 / 380V 50 / 60hz |

| 填充精度 | +-0.5% | 机器重量 | 360KGS |

| 空气压力 | 0.4-0.6MPA | 机器尺寸 | 3500 * 1580 *2190毫米 |

快速详情

类型:灌装机

条件:新的

应用:饮料,化工,商品,食品,医疗

包装类型:瓶子,罐子,纸箱,表壳,直立袋

包装材料:玻璃,金属,塑料

自动等级:自动

驱动类型:电气和空气

电压:220V / 380V

功率:1.6KW

产地:中国上海(大陆)

品牌名称:VKPAK

尺寸(L * W * H):2200X2100X2200MM

重量:450公斤

认证:CE ISO

提供售后服务:工程师可在海外维修机械

产品名称:2合1自动瓶装和液体封盖机

材质:SUS304 / 316

功能:液体填料

用法:饮料包装

填充材料:流动液体

瓶型:圆瓶

容量:40-150B / M

保修期:12个月

A 2-in-1 automatic bottle filling and capping machine for liquid is a piece of equipment used for filling bottles with liquid and then capping them. The filling and capping process is done automatically, which saves time and reduces the need for labor. This machine is used in various industries, including food and beverage, pharmaceuticals, and cosmetics.

The filling part of the machine works by using a volumetric filling method to fill the bottles with the liquid product. The volumetric filling method ensures that the bottles are filled with the correct amount of product, which is important in industries where the correct dosage is crucial. The machine can fill a range of bottle sizes and types, making it versatile for use in different industries.

The capping part of the machine uses a mechanical method to place the caps on the filled bottles. The caps can be of different sizes and shapes depending on the type of product being packaged. This machine ensures that the caps are securely placed on the bottles to prevent any leaks or spills.

The 2-in-1 automatic bottle filling and capping machine is an essential piece of equipment for any manufacturing process that involves liquid products. It can increase productivity, reduce labor costs, and ensure that the products are packaged consistently and correctly. The machine is easy to operate and can be customized to meet the specific needs of the business, making it a valuable investment.