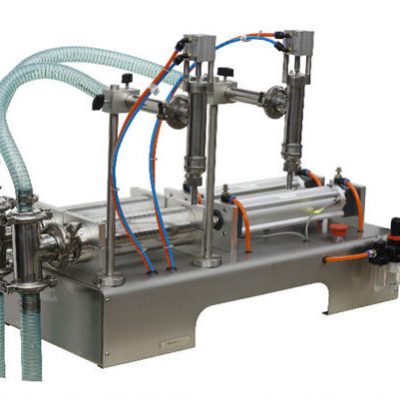

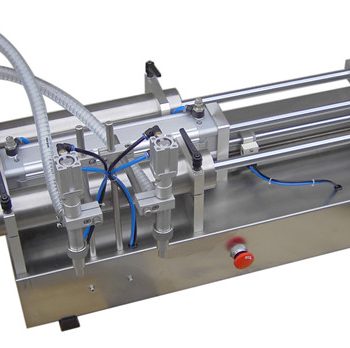

我们的自动旋转星轮灌装封盖机适用于灌装水稀薄到中等厚度的产品,如药液,爽肤水,烫发乳液,空气清新剂,护肤品等。它们结构紧凑,占地面积小,外观美观,调整方便,适用性广,可广泛应用于制药,农药,日化,食品等行业。

在这些系列中,灌装和封盖动作由精确的机械传动驱动,这可以有效地保证产品的质量。所有工作站,包括灌装,盖帽喂料,封盖都配备在一个星形轮周围,因此可以大大减少工作空间和所需的操作员。自动和不间断的生产模式有助于保证您所需的产量。我们选择好的材料和零件来组装我们的机器。所有零件均与进口食品级不锈钢制成,所有气动和电气零件均为德国,日本或台湾的知名品牌产品。正是创新设计和优质零件确保了这一系列机器在国内液体包装市场中绝对占据领先地位。

我们的旋转星轮灌装和旋盖机特别适合大批量生产的单一产品。

生产流程:

填充---进料插件---压入式插件---进料盖---封盖

根据您的需求进行设计。

主要技术指标

快速详情

类型:旋盖机,灌装和封盖机

条件:新的

应用:饮料,化工,食品,机械五金,医疗,化妆品,医药,化工等

驱动类型:电动和气动

自动等级:自动

电压:380V

功率:4kw

包装类型:瓶子

包装材料:玻璃,金属,塑料

产地:中国上海(大陆)

品牌名称:VKPAK

尺寸(长*宽*高):1670 * 1350 * 1675

重量:600公斤

认证:ISO9001

提供售后服务:工程师可在海外维修机械

质量控制体系:ISO9001:2008

现场管理系统:5S

An automatic cream filling and capping machine is a highly advanced packaging machine that is specifically designed to package creams and lotions into various types of containers such as jars, bottles. This machine is essential for businesses in the cosmetics industry who want to streamline their packaging process and increase their productivity.

One of the key benefits of an automatic cream filling and capping machine is its ability to fill and cap containers at a high speed. This is achieved through the use of advanced automation technology that allows for fast and accurate filling and capping. In addition, the machine is highly versatile and can handle a wide range of container sizes and shapes, making it ideal for businesses with diverse product lines.

The machine works by first filling the containers with the cream or lotion using a dosing pump that accurately dispenses the required amount of product. The containers are then capped using a capping head that tightly seals the product to ensure freshness and prevent spillage. The capping head can be customized to accommodate different types of caps such as screw caps, flip-top caps, and snap-on caps.

One of the key features of an automatic cream filling and capping machine is its ease of use. The machine is equipped with a user-friendly control panel that allows for easy adjustment of settings such as filling volume, capping torque, and speed. This makes it easy for operators to set up and operate the machine, reducing the risk of errors and improving overall efficiency.

Another important feature of an automatic cream filling and capping machine is its high level of hygiene. The machine is designed to be easy to clean and sanitize, with smooth surfaces and minimal crevices that can trap dirt and bacteria. This is particularly important in the cosmetics industry, where hygiene is essential for ensuring product quality and safety.

In conclusion, an automatic cream filling and capping machine is a valuable investment for businesses in the cosmetics industry. With its advanced automation technology, versatility, ease of use, and high level of hygiene, this machine can help businesses increase their productivity, improve their packaging quality, and stay ahead of the competition. When choosing a cream filling and capping machine, it is important to consider factors such as production capacity, container size and shape, and the type of cream or lotion being packaged.